Eco Recording Studio Design

Sustainable buildings struggle with acoustic control. Can we design an eco music studio that achieves both acoustical and green goals?

Part I presents the acoustics and a building-integrated solar power system for the conceptual recording studio. First, acoustical parameters were chosen for the control room and live room. Next, geometry was assigned based on the desired acoustics for each room. These geometric constraints were used to size a recording facility and derive electrical loads. Finally, a photovoltaic system was sized to meet the estimated power demands.

Part II presents green acoustic treatments for the studio’s control room. To qualify, a material had to be recycled, natural, abundant or renewable. The findings suggest that high quality acoustic treatments can be implemented almost entirely with sustainable materials.

Part I: Proposed Architectural Acoustics & Photovoltaic System

(Free Instant Download)

PURPOSE

Green goals present challenges to acoustical design. An acoustically optimized design places constraints on structural form, building materials, passive heating, ventilation and natural lighting; thus it may conflict with green building practices.

The purpose of acoustical design was to define parameters for a recording studio control room and live room, identify architectural dimensions to achieve those parameters, and derive electrical appliance loads from the architectural dimensions.

Because recording studios may be operated for extended hours, a green studio is expected to consume more energy than an equivalent sized net-zero residential building.

The purpose of solar power system sizing was to estimate the portion of energy demand that can be satisfied by building-integrated photovoltaics (specific to the Vancouver region).

It is hoped these findings may eventually be used as constraints to help guide a more rigorous design effort by a team of professionals.

SUMMARY OF RESULTS

The conceptual control room is a ‘Live-End, Dead-End’ room with splayed walls. The design facilitates critical listening in an environment that is not acoustically dead (An alternative is a Non-Environment control room, offering better critical listening at the expense of liveliness). A simplified acoustic model (an “equivalent volume rectangular room”) was used to roughly simulate reverberation properties. By adjusting room parameters, the reverb time and initial time delay gap can be tuned to near-optimal values, shown to be about 0.345 seconds and 20 milliseconds, respectively. A live room of 20200 ft3 room with a reverberation time of 0.67 seconds is shown to be a suitable recording space for this studio.

Peak demand for the studio is expected to be 23.2 kW, based on known equipment loads and the dimensions specified by acoustical design. 102 kW of photovoltaic module capacity with 30 kW of inverter capacity is the minimum PV system for the facility to be net-zero on a day with 3.7 peak sun hours (the annual mean for Vancouver). Up to 56% of the required modules will fit on the expected roof of the facility, placing a limit on the building-integrated PV potential. This result demonstrates conflicting design objectives: the studio requires more power than the off-grid building-integrated photovoltaics can provide.

It is recommended that remote photovoltaic arrays utilizing 2-axis sun tracking be investigated as a method to meet the excess power demand; also, future eco-building design should focus on minimizing energy consumption. Feasibility analysis, cost-benefit-analysis and detailed assessment of PV potential need to be conducted with input from experts. Detailed design must be performed by an architectural firm with feedback from engineers and green building professionals.

Part II: Sustainable Acoustic Materials

(Free Instant Download)

SUMMARY

Part II presents materials for acoustic treatment in the studio’s control room. To qualify, a material had to be recycled, natural, abundant or renewable. Preference was given to materials that can be locally sourced in the Vancouver region. The findings suggest that high quality acoustic treatments can be implemented almost entirely with sustainable materials.

Wool, hemp, stone wool and recycled fabric products provide excellent sound insulation. Two examples are Roxul Safe’n’Sound™ and Bounded Logic UltraTouch™. Green materials for building framed isolation walls include salvaged timber, bamboo lumber and Homasote 440 SoundBarrier®. Isolation walls may also be built using rammed earth, hempcrete or sand-filled concrete blocks.

Green sound absorption products are available, made from natural or recycled materials. An acoustic control wall with a built-in broadband absorption system can be constructed using mostly sustainable materials.

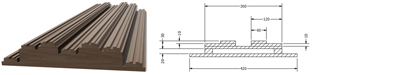

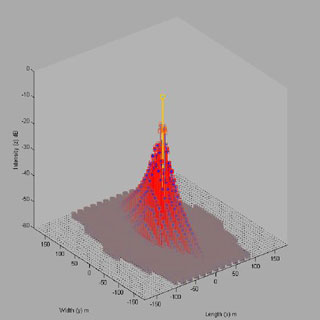

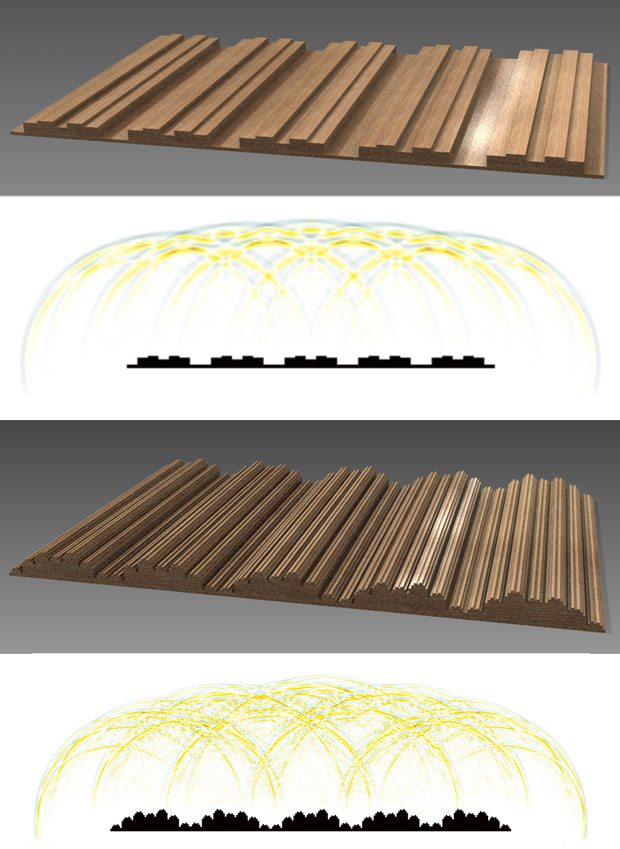

Wood-like acoustic floors and reflective surfaces can be built from salvaged wood or rapidly renewable resources like cork tile and bamboo lumber. These materials can also be used to constructed acoustic diffusers on-site. Most diffusers are geometrically complex and hard to build; therefore, modular ‘stepped’ diffusers have been numerically optimized to facilitate simple construction using wood working tools. For surfaces that require a hybrid absorptive-diffusive treatment, the hybrid surfaces patented by RPG® are high performance, LEED certified, low profile and elegant.

Modular acoustic diffuser designs and near field scattering simulations. The optimized stepped diffuser (top two images) is designed for simple DIY construction. The fractal diffuser (bottom two images), made from repeatable elements, can be produced by low precision manufacturing, or be manually built by a carpenter. Both diffusers can be constructed from local materials. Learn more about diffusers here, or see how optimization was used to design them.

by Tim Perry